It’s time for some solid-state battery tough talk. Solid state batteries are the next step in the evolution of electric vehicles, but they are far from the panacea that they are presented as. Let’s take a deep dive into what solid state batteries are, what challenges they solve and importantly: what challenges remain even in a world full of solid electrolyte batteries.

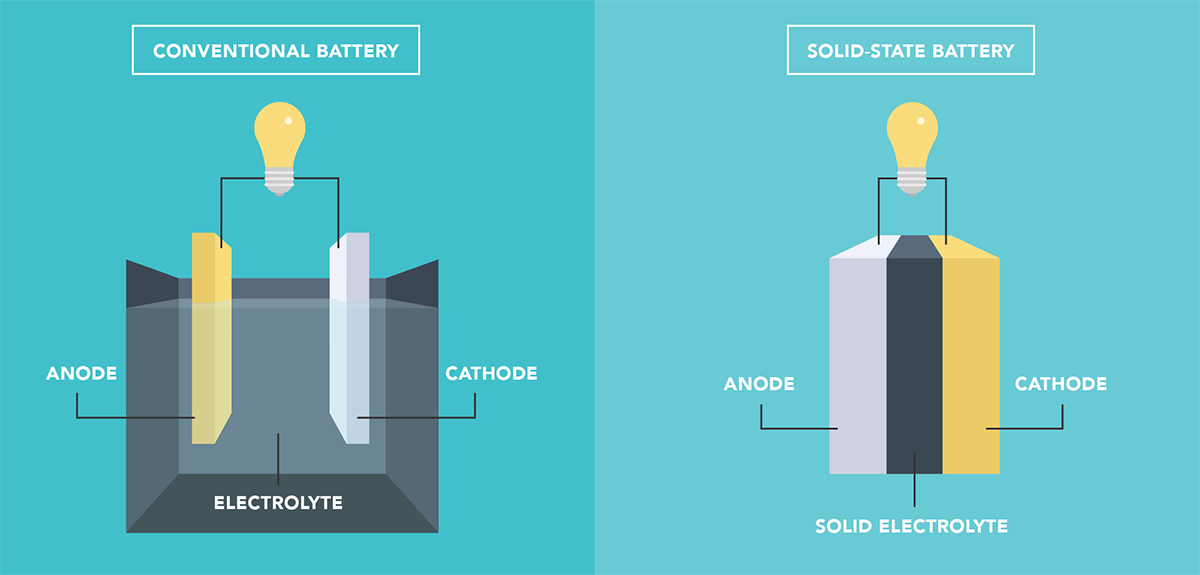

First, what is a solid-state battery? Put simply, it’s a battery with a solid rather than liquid electrolyte. At the moment, every EV has a battery with a “liquid” electrolyte, although in reality it’s more of a paste or gel. Solid state batteries promise greater energy density, faster charge times, and longer cycle lifetimes but there are challenges to overcome.

What’s taken so long? Well, it mainly has to do with safety. In a battery with a solid electrolyte and lithium chemistry (solid state EV batteries will still use lithium), dendrites form within the electrolyte over time and can pierce the anode or cathode causing a short and subsequent fire. This appears to have been resolved in the latest designs but scaling up to mass production is a different challenge.

Having a battery that is capable of charging rapidly is a separate matter from onboard wiring and charging stations that can supply the power we’re talking. Right now, 350 kW stations are the fastest available in America and market penetration is low. There are far more ~255kW Tesla plugs than CCS 350 plugs around, but that said let’s do the math. A Lucid can average ~180 kW from 0-80% which means a 37-minute stop to go from 0-80% SOC. Assuming you could sustain 350kW for that 0-80% run you could drop things to 18.5 minutes. That’s a solid charging time and would be fantastic for the 416 miles you get in a Lucid. But what if you wanted a 400-mile EV truck, like a Ford Lightning?

Well, with an average highway consumption of 1.8 mi/kWh, you’d need a 223 kWh battery in a Lightning. No problem with a solid state, that would fit in the current footprint of the truck easily. (Let’s disregard the weight increase and corresponding efficiency decrease for now.) In this scenario, 0-80% at 350 kW (320 miles of range added) would take 31 minutes.

For the record, 350 kW is a TON of power. That’s 30 homes in Florida with the AC cranked up while they bake a turkey for thanksgiving and do the laundry.

What would we need to do to get to a 5-minute charge on that Lightning? Back to the math.

80% of a 223-kWh battery is 179 kWh (rounding up). To deliver that, plus the inherent 10% loss in DC fast charging, you’d need to supply 2,362 kW to the charging station, or about the power consumption of nearly 10 Teslas Supercharging at their fastest rate.

New 1,500V 600A GB/T connector

Now how would we support such an insane charge rate? Well, you have two options: raise the current, or raise the voltage. Right now, 500A is the max current on a vehicle charge cable in the USA and as it is, a 500A flexible cable isn’t overly flexible and must be liquid cooled. The new GB/T standard in China bumps that to 600A and 1,500V but that’ll only get you to 900kW, less than half of what we need. So, the answer is either: bump voltage to 4,000V (talk about serious arcing potential with DC), or crank up the current even further. Even at 1500 VDC you’d need to push nearly 1,600 amps which would require cables the diameter of salad plates.

Solid-state batteries are a big step in the right direction, but the bottom line is that a 5 minute charging big-battery EV is a pipe dream that has nothing to do with battery technology and everything to do with physics. Charge rates will improve, but promising a 5 minute charging pickup truck or big SUV is a promise that cannot be fulfilled.