It’s all over the news: Cybertrucks are rusting and folks are mad. Me? I’m surprised they are surprised. If you own a stainless steel fork or knife and a dishwasher, rusty bits on stainless steel should be familiar. But why does it happen? Isn’t stainless steel… well… stainless? Not quite.

One of the benefits of co-owning a materials engineering company is: not only do I own a stainless steak knife, I also own an electron microscope I can put the knife in. Let’s dive 3,000 X into a rust spot and do a little energy dispersive x-ray spectroscopy while we’re at it.

First things first: What is stainless steel? It’s steel that’s been alloyed with other elements to reduce corrosion, the most important of which is chromium. (Cr doesn’t just inhibit corrosion, it also increases the hardness of the alloy.) Depending on the alloy, molybdenum, nickel, manganese, and others can be blended into the mix as well.

The mix is the essential part here. Making an alloy is like making a cake. No mater how long you let the Kitchen Aid beat your batter, you’ll still see clumps of something in there. And so it is with a metal alloy. Whether we’re talking some cheap and undisclosed alloy in your $0.99 Wallmart fork, or an expensive 904L stainless steel alloy, there will be clumps in the batter.

What alloy does Tesla use? We don’t know for sure, but it sounds like it’s 301 stainless. Tesla says it’s a “custom alloy” but that doesn’t mean much. All it means is “hey, I asked for 11.05% Cr instead of their stock 11.04% Cr alloy.” Anyway, 301 stainless is more ductile tharesistantn more corrosion resistant alloys which makes it easier to form into body panels.

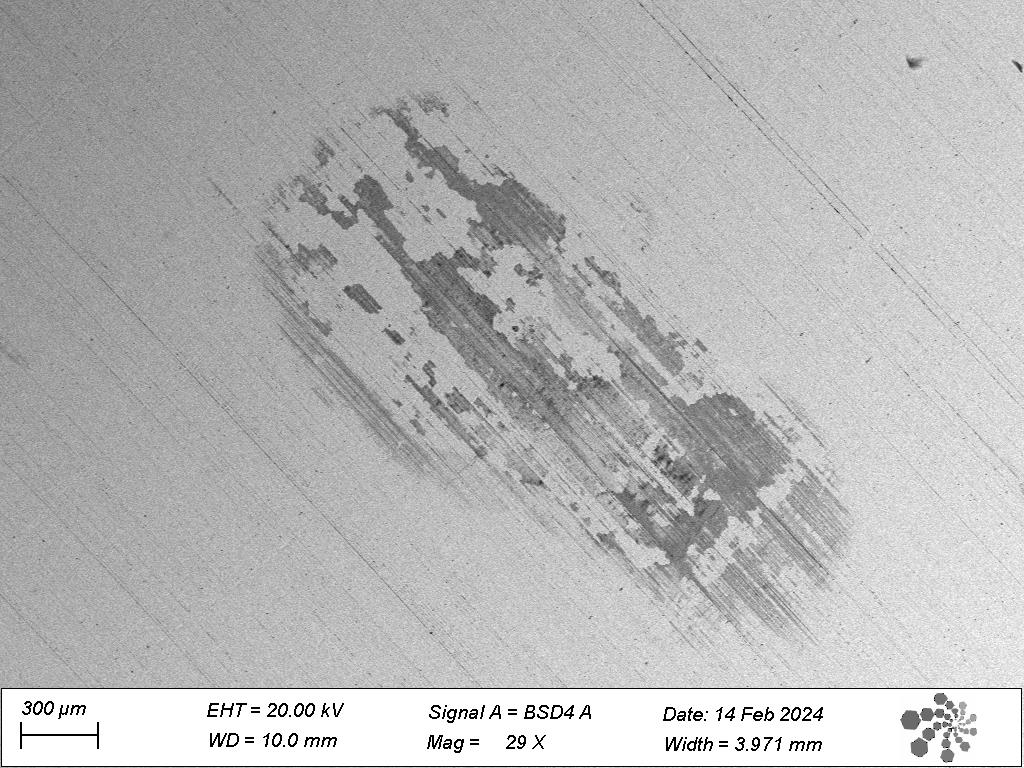

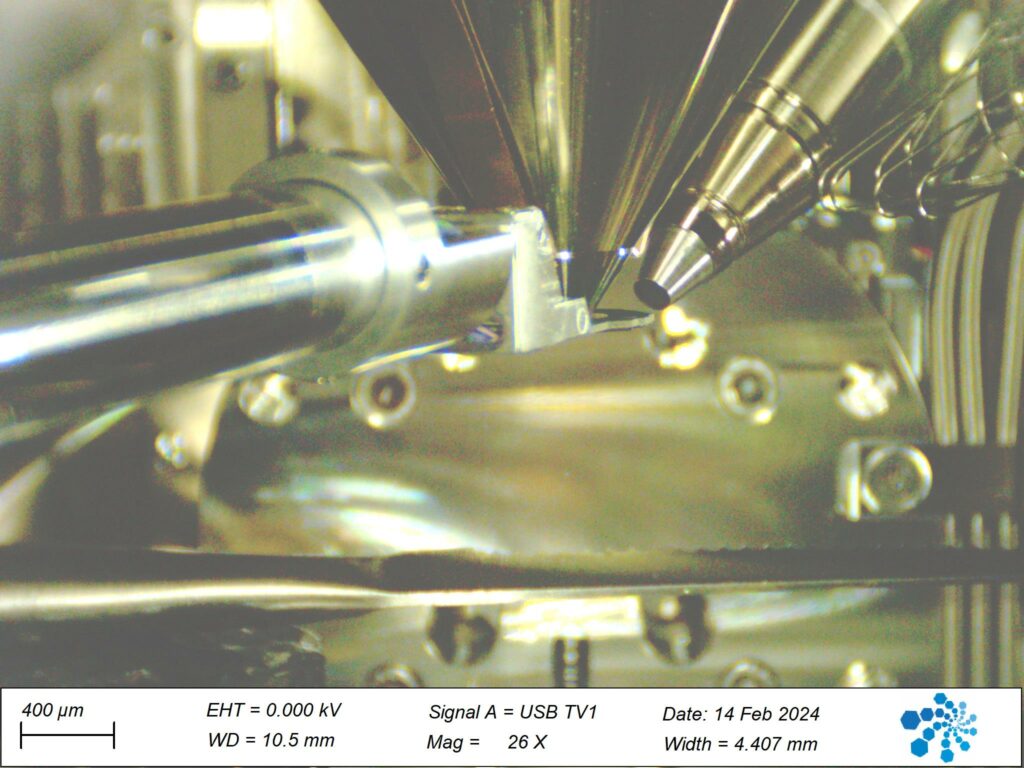

Let’s get to the knife. Why a knife? Because I don’t have a Cybertruck to cut up, and a Tesla wouldn’t fit in my SEM anyway. (SEM stands for Scanning Electron Microscope in case you’re wondering.) As you can see in the first image taken by a stereo optical microscope, there’s a visible rust spot on this steak knife as well as some small black spots, that’s where a “blob” of iron oxidized. Since this was a cheap knife, the blob is easily seen at just 29 X in the SEM. You can see that there are actually voids where the iron oxidized and fell off.

What’s magical about stainless steel however is that this isn’t really a functional problem because unlike a regular steel alloy, the corrosion will generally not progress further. Beyond this area (where the alloying materials were not well blended), the chromium oxidizes (in the area where it is well blended) and creates a passivating layer of chromium oxide to protect the underlying surface from rusting.

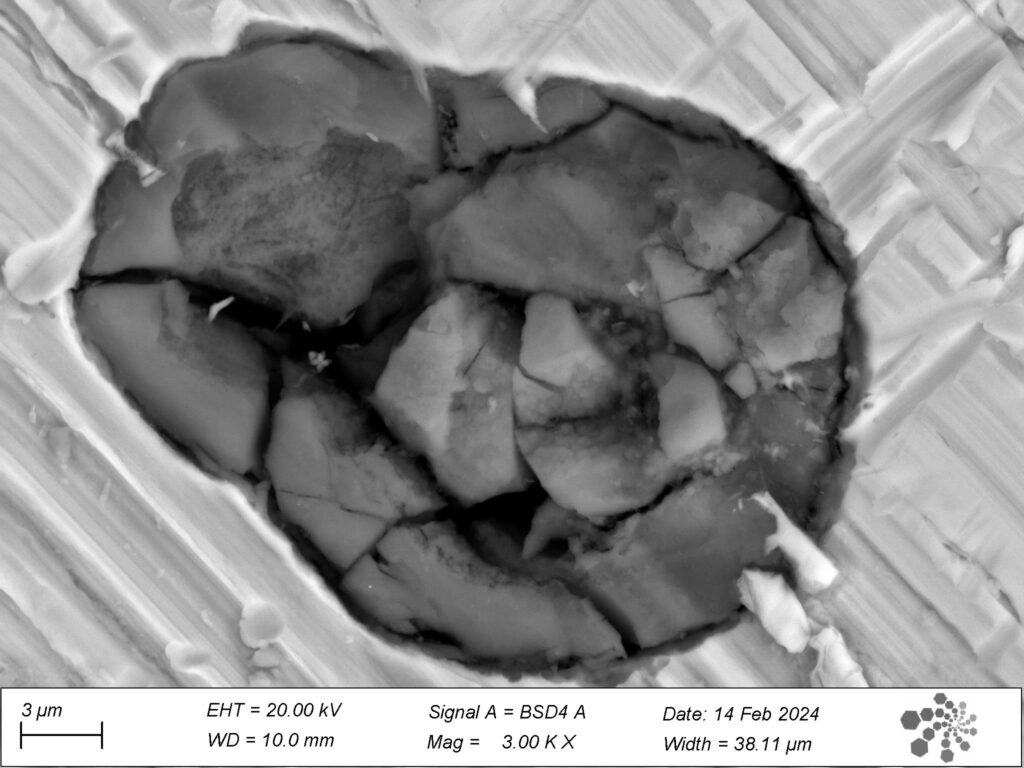

Moving on to the photo that looks like a blackhead from your worst nightmares, this is classic stainless steel pitting. Basically the chlorides in dishwasher detergent strip the protective oxide layer off the stainless steel allowing the corrosion to travel ever deeper down the rabbit hole. In the multi-color image you can see the high presence of oxides (orange) and the absence of iron (teal) and reduced presence of chromium (red).

So what do you do about it if you have a Cybertruck? That depends on your goal. If you want to prevent it, you need to make sure you don’t expose the stainless steel to salts, acids, bleach, etc. Adding a protective layer like a clear wrap will also help. A thin layer of a light oil-based product would also not be the worst idea as it will create a hydrophobic barrier.

What about scrubbing it? Well, that’s what this knife has been through which is why in the “black head” photo you’ll see the crazy stripes, those are fine scratches on the surface where it’s been scrubbed with a green Scotchbrite. While this will remove the visible corrosion from the surface, it won’t fix the issue and long term pitting and corrosion will still occur until the iron has been consumed, or something else pasivates the oxidation or coats the surface (like the chromium oxide).